Storage Tanks

Effective Storage Tank Compliance Program

The Blackledge Group understands the challenges owners and facility managers face ensuring compliance with the myriad of complex local, state and federal regulations and guidelines that govern fuel and petroleum product storage systems. We have provided regulatory support to transportation authorities, port authorities, municipalities, utilities and other local and state agencies; and to a wide array of commercial and industrial clients.

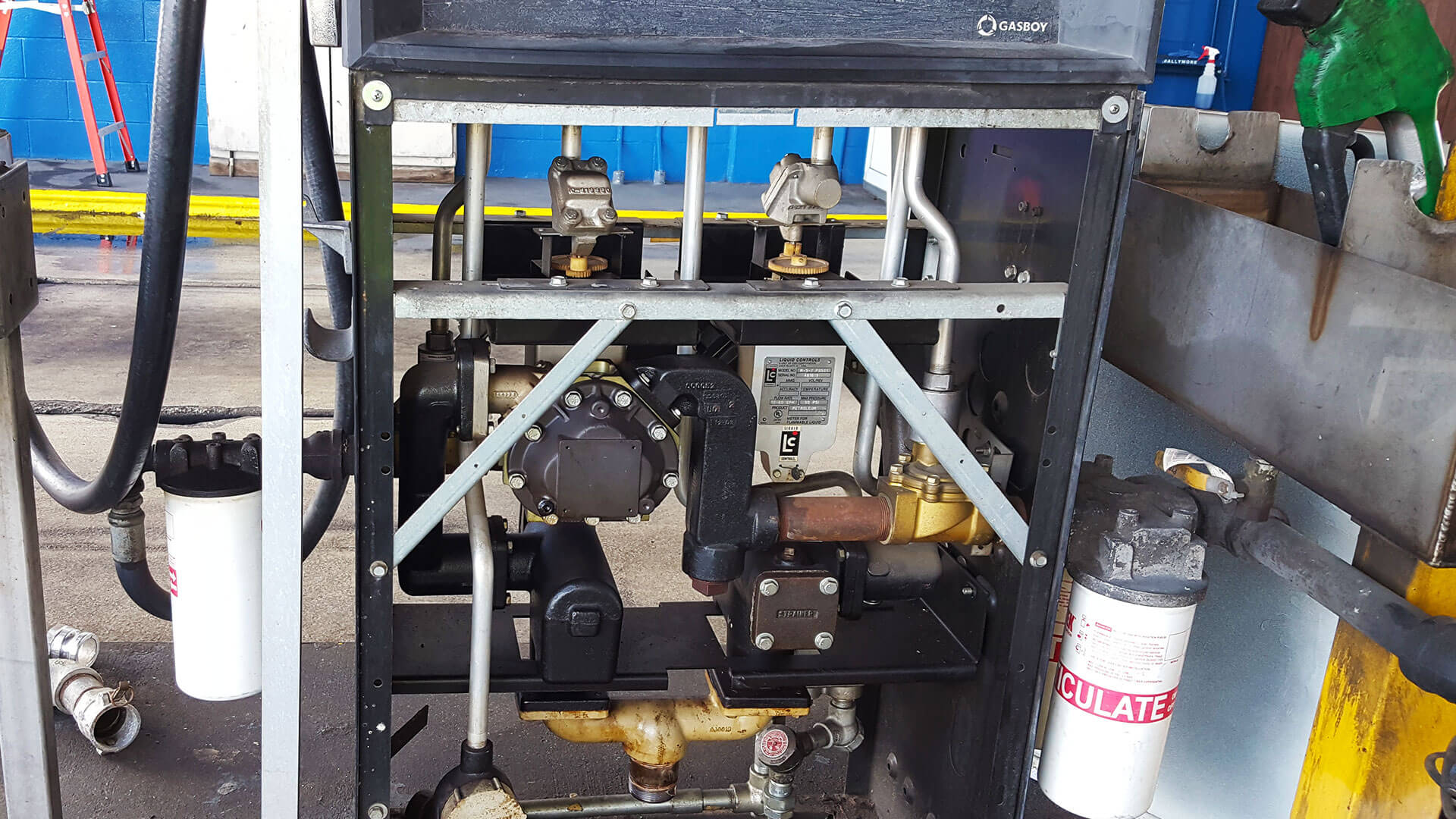

Many of the regulatory issues associated with the management of aboveground storage tank (AST) and underground storage tank (UST) systems are the result of improper operation and maintenance. At The Blackledge Group, we work with maintenance, engineering and environmental staff, facility managers, and business owners to create an effective Storage Tank Compliance Program to ensure your storage systems meet or exceed regulatory requirements.

Benefits of a Comprehensive Storage Tank Compliance Program

- Ensure operational continuity by passing regulatory inspections the first time

- Minimize enforcement actions and notices to comply

- Eliminate penalties resulting from noncompliance issues

- Control environmental impact caused by undetected releases of petroleum products

- Eliminate costly cleanup expenses related to discharges

- Proactively address operation and maintenance issues through scheduled maintenance activities

- Manage costs associated with upgrades and replacement of faulty components

Developing a Storage Tank Compliance Program

At The Blackledge Group, we develop Storage Tank Compliance Programs that are site specific and tailored to your individual facility. Key elements of our comprehensive and proactive programs and services offered include:

- Developing regularly scheduled inspections of all storage system components.

- Ensuring product and equipment compatibility.

- Preparing required regulatory notification and system registrations.

- Performing regular testing and evaluation of all system components to include hydrostatic testing of sumps, lines, and leak detection systems.

- Ensuring results of operability tests and functionality tests are recorded and kept on file at the facility for easy reference by inspectors.

- Maintaining records on-site to include permits, spill bucket tests, line tests, and any other required documentation.

- Reviewing financial responsibility forms for accuracy,

- Conducting training programs and ensuring key personnel are trained and certified in all aspects of operations including safety, emergency response, hazardous material handling, and compliance training.

- Preparing and updating Facility Response Plans (FRPs) and Spill Prevention Countermeasure and Control (SPCC) plans.

- Providing construction management of contractors during storage system installations, modifications, and repairs.

- Overseeing spill response operations and conducting environmental assessment and remediation.

- Performing system decommissioning, tank closures, and closure assessments.